Solar PV Performance Analysis: 2.2. String Availability

- Willow Energies

- Sep 13, 2024

- 2 min read

Updated: Oct 25, 2024

After ensuring the inverter availability is as high as possible, it’s also good practice to check string level availability.

As a reminder:

If there are 10 inverters on a site each with the same capacity, and 1 is not producing, the available capacity drops by 10%.

If there are 100 strings on a site each with the same capacity, and 10 are not producing, the available capacity also drops by 10%.

So non-producing strings also have a big impact on site performance, hence why it’s important to not just check inverters but also string availability!

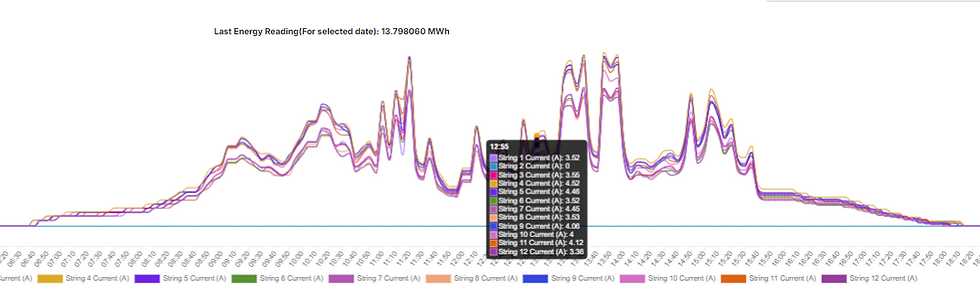

On the above example we can see that string #2 is showing 0 Amps current. This string needs to be checked on site to rectify the source of non-production (loose MC4 connector, string fault, blown fuse etc).

Standard monitoring software should generate automatic alerts based on string failures (e.g. “generate alert if any string current =0 for 2 hours”). It should also be able to differentiate between single or double strings so that you don’t get false alerts based on normal plant design.

Certain inverter manufacturers such as SolarEdge or SMA don't like sharing string current data with 3rd party monitoring software platforms. If your monitoring system doesn’t generate string alerts then it can be worth manually creating scripts or macros to download data from the logger and automatically flag any strings that are not generating current when irradiance is >50 W/m2.

Watch out for negative current

String level data is not just important to check for availability, it can also be critical in looking for serious issues such as insulation resistance faults or short circuits.

In the above example we see one string gradually showing more and more negative current from 08:00 until at 13:40 when there is a big failure, after which several strings display around -10A negative current. Negative current is a serious issue which typically means there is a short circuit often leading to overheating/fire.

This advanced “warning” could only be seen by looking through string data, in this case there was no inverter warning or fault until the incident happened.

Such negative current situations should be treated with great care, as there can be life-threatening current flowing through the cable tray or module frames during the day. It’s highly recommended to wait until irradiance has reduced so that string current is <0.5A before attempting to repair such issues.

Now that we’ve ensured all equipment is available to produce energy, next time we’ll start looking at the major sources of underperformance!

Comments